Troughers

Troughers Engineering Guidelines

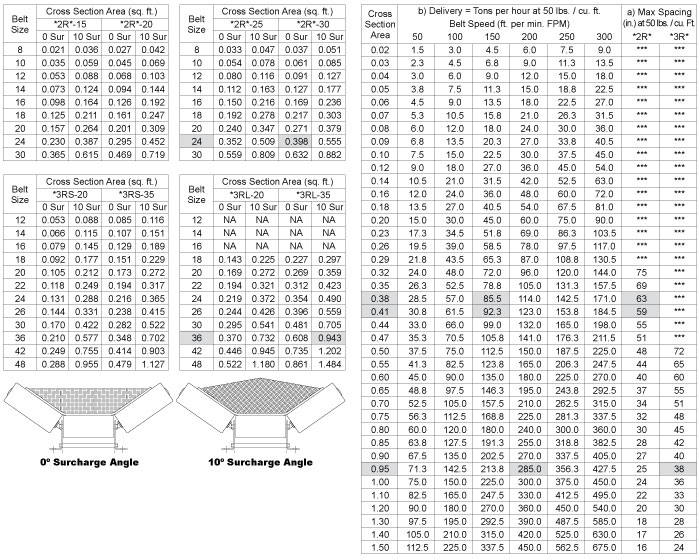

Many variables affect actual conveyor delivery - your application will require specific engineering that Ralphs-Pugh does not provide. The following information is for comparative purposes only and is only provided for 50 pounds per cubic foot material density. Find cross sectional area (Sq. Ft.) for 0 and 10 degree surcharge of various standard Troughers on charts on left. See the theoretical conveyor delivery (Tons per hour) and frame spacing (Max. center distance inches) on charts for various sectional areas (sq. ft.) and Belt speeds (FPM) at 50 pounds per cubic foot density. See illustration and examples below to better understand the data provided.

Installation Notes:

a) Spacing of units will be dictated by troughability of belt as well as by load capacity of troughing unit. Where *** is indicated, spacing should be limited to maintain troughability of belt. Inches shown indicate the maximum center distance (at 50 lbs./Cu. Ft. materials) so as not to exceed 100 pounds per 2 roll units and 150 pounds for 3 roll units. In general, spacing should not exceed 36 to 48 inches for troughability or inches indicated for unit load capacity. Consult your engineering for specifics.

b) Roller diameter as well as belt speed and load per unit affect bearing life. For ball bearings, limit 1.9" diameter roll units to 150 FPM, 2.88" diameter roll units to 300 FPM. For bushing style bearings, limit 1.9" diameter roll units to 50 FPM, 2.88" diameter roll units to 100 FPM.

c) Pulley top elevation to bottom of belt trough affects belt stress and bearing loads in rollers. Typically, for *2R-30*, locate the top of the pulley above the trough V by 1/2" for a 12" belt to 1 1/2" for a 30" belt width. For *3RS-20, locate the top of the pulley level with the top of the center roll. For *3RL-35, locate the top of the pulley 1/2" above the top of the center roll.

d) Spacing for first unit from pulley affects belt stress and bearing loads in rollers. Typically, for *2R*, use *2R*-15 as transition unit - offset the distance from the pulley by one belt width. For *3RS, offset distance from the pulley by one belt width. For *3RL, offset the distance from the pulley by 1.5 x belt width.

Examples:

(Shaded in the tables above)

On the left, *2R*-30 @ 0° surcharge x 24" belt = .398 Sq. Ft.

On the right under "Cross Section Area", between 0.38 and 0.41

Sq. Ft. @ 150 FPM = approx. 90 TPH and maximum spacing of approximately

60 inches, but should be reduced for troughability.

On the left, *3RL-35 @ 10° surcharge x 36" belt = 0.943 Sq. Ft.

On the right under "Cross Section Area", close to 0.95 Sq. Ft. @ 200 FPM

= approx. 285 TPH and maximum spacing of 38 inches based on unit load

limit.