Bearings & Bearing Inserts

Ralphs-Pugh offers a broad range of bearings and bearing inserts to meet the most demanding operating environments. We control our bearing manufacturing process from design through tooling, material selection, injection molding, and assembly. We’ve set our standards high to ensure that our products meet or exceed our customers’ expectations. Ralphs-Pugh plastic housed bearings are available with labyrinth seals for applications requiring the ultimate protection against dirt, dust, and other contaminants that adversely affect bearing performance and useful life. If you do not see a particular bearing style you require, please contact our customer service department for assistance. Ralphs-Pugh also offers private label programs.

Products include:

Commercial Grade

Most suitable for light to moderate loads and speeds, commercial grade bearings have hardened steel balls and raceways, and are lubricated with light oil. Grease packed units may be ordered for driven applications. Commercial bearings do not have ball retainers, and consequently the balls will contact each other during operation and are a source of conveyor noise. Commercial grade bearing styles include:

- Plated Steel Bearings / Metal Stamped and Plastic Housings

- Stainless Steel Bearings / Plastic Housings

ABEC-1 Precision

ABEC-1 precision bearings are most suitable for moderate to heavy loads and higher speeds. These bearings have hardened and ground balls and raceways with a ball retainer, and are grease packed at the factory. Several seal or shield options including Contact Rubber Seals (2RS) and Non-Contact Rubber Seals (LLB), or Non-Contact Metal Shields (ZZ) are available to help retain the grease and isolate the bearings from contaminants. ABEC-1 bearings are quiet and typically have a significantly longer life than commercial bearings. Ralphs-Pugh ABEC-1 bearing inserts are available in the following configurations:

- Plastic Housing with Labyrinth Seal

Provides the highest level of protection from exposure to contaminants. - Plastic Housing without Labyrinth Seal

- Stamped Plated Steel Housing (Metal Tubes Only)

When plastic housings should not be used due to higher loads.

Should be swaged into the tube for optimum performance. - Machined Steel Housing (Metal Tubes Only)

Designed for heavier loads. Ideal for SNUBBER and BELT WRAP roller applications.

Typically welded into the tube. Swaged options are available in select sizes.

Bushings:

Non-ball bearing bushing units are designed for light to medium loads conveyed at low speeds. Typically bushings are used in push and gravity conveyors. They are ideal for sanitary, rust and corrosion resistant, low maintenance wet or dry applications. Bushing inserts are available in Ultra (Acetal plastic with internal Teflon lubricants), CS2 Acetal, UHMW, and ABS plastic. Bushing adapters are available in nylon, stainless steel, carbon steel, and Ultra. Bushings are identified with a 5 Prefix in the part number. Example - 5B5

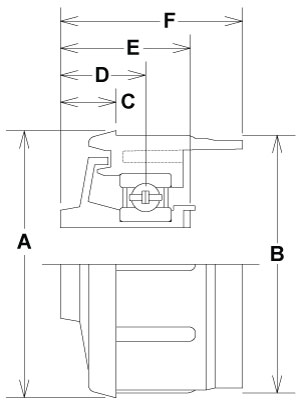

Definition of terms and dimensions used in bearing descriptions in this section:

A Dim: Outside diameter of the flange

B Dim: Outside diameter of the body

C Dim: Distance from the hub to the backside of the flange (bearing offset)

D Dim: Distance from the hub to the centerline of the ball compliment

E Dim: Distance from the front to the back of the hub

F Dim: Total length

Bore: Size and configuration (hexagonal or round) of the bore

Bearing: ABEC-1 precision or commercial non-precision bearing used in a bearing insert. Load rating for bearing is not roller load rating. Please refer to specific roller pages for roller load capacity.

Bearing BDLR: Basic Dynamic Load Rating of the ABEC–1 precision bearing: Load at which 90% of a group of bearings will still be successfully spinning at 600 RPM after 1,000,000 revolutions.

Bearing Load Rating: Load rating for commercial bearings

at 600 rpm. Determined utilizing the number of balls in the bearing and

their size. This load rating is not the roller load rating. Please refer

to a specific roller page for the roller load capacity.

Races: These refer to the inner and outer surfaces the

balls ride on. Precision ball bearing races utilize bearing quality steel.

This material is then heat-treated to uniform hardness and ground to a

micro-finish. Non-precision ball bearing races are made with hardened

steel that provide an economical and smooth finish.

Balls: Balls in non-precision bearings are manufactured from hardened steel. These balls are then loaded into the raceway utilizing a full compliment of “loose” balls. Precision balls are made of hardened chrome alloy steel and separated in the raceway with a ball retainer or cage. This “cage” separates the balls, which greatly minimizes the noise and contact friction between adjacent balls. This also permits higher operating speeds.

Bearing Seals and Shields: Precision bearings are produced with seals or shields.

Seals: Seals are normally made of rubber and can be a “Contact Seal (2RS)” or “Non-Contact Seal (LLB)”. Both types of seals are generally in contact with the outer raceway, however, the Contact Seal (2RS) will also come into contact with the inner race of the bearing. Therefore, while offering a higher degree of contamination resistance versus a shielded bearing, this seal will also cause increased frictional torque.

The Non-Contact Seal (LLB) consists of a synthetic rubber bonded onto a steel backing ring, which is fastened to the outer race for positive sealing. Both sides of the seal edge are provided with corrugations to create an alternating series of wide and narrow gaps along the inner ring V-groove seal surface. This causes a complete labyrinth effect. The frictional torque on this bearing is low, it can be safely used in dusty environments, and is excellent for powered applications.

Non-Contact Shields (ZZ) are metallic shields press fit into the outer ring to keep foreign objects from getting into the bearing. This is a general purpose, prelubricated bearing with low frictional torque, and is widely used in both gravity and powered applications.

Labyrinth Seal: A series of intricate passageways manufactured into the plastic bearing housing designed to prevent foreign materials and contaminants from getting into the balls and raceways.

Service Life: The life of a bearing is dependent on numerous factors; load, speed, temperature, humidity, airborne contaminants, bearing materials, and lubricants. Load duration and shock loading also affect service life. Precision bearings are affected differently than commercial bearings and each factor should be considered when selecting a bearing or bearing unit. In applications where chemicals are a factor, the proper selection of engineered plastics and bearing material is critical.

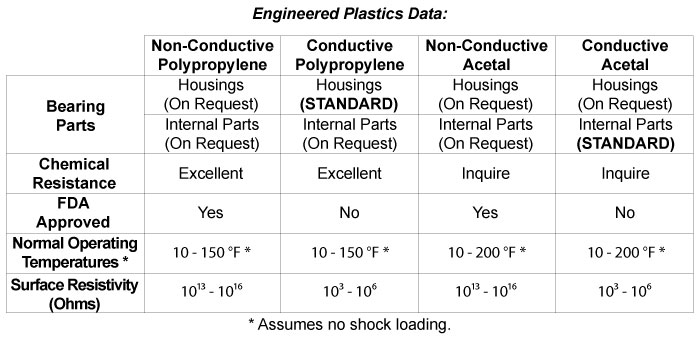

Static Electricity

Static electricity is the release of stored electricity created by the sliding, rubbing, turning or separating of material that generates electrostatic voltages. Plastics, fiberglass, rubber, textiles, etc. are prime generators of static electricity, and under certain conditions can build up to 30,000-40,000 volts.

When an electrostatic charge occurs in an insulating material, the built-up charge tends to remain in the local area of contact. It will discharge in the form of an arc or spark when the material comes in contact with a body at a sufficiently different potential, such as a person or microcircuit. If electrostatic discharge (ESD) occurs to a person, the result can range from a mild to very painful shock. In extreme cases, ESD can cause loss of life. ESD can also trigger explosions or fire in any environment containing flammable liquids, solids, or gasses. Since conveyor rollers are often used in these environments it is critical that they provide a means to safely dissipate the electrical charge.

Plastic parts and components are classified as insulating materials having typical surface resistivity of 1016 – 1017 ohms/sq. Most electrically conductive plastics today contain insulating base resins and conductive fillers or reinforcing agents to provide for static electricity dissipation. Electrically conductive plastics are defined as:

- Dissipative Composites - 105 - 1011 ohms/sq resistivity

- Conductive Composites - 102 - 104 ohms/sq resistivity

- ESD Shielding Composites - 10-4 - 101 ohms/sq resistivity

See the chart below for the surface resistivity for the above conductivity ranges.

Installation Recommendations for Bearing Units with Plastic Housings

Preparation

- The inside of all tubes must be deburred.

Installation

- Scuffing must be avoided – Scuffing is indicated by a build up of “shredded” or “rolled up “ plastic between the flange of the bearing and the end of the tube.

- Bearing unit should be pressed into the tube with a device that conforms to the face of the unit to exert even pressure.

- Avoid excessive and non-uniform pressure on any one component.

- Bearing units should not have any preload from spring and crimp positioning.

- Shaft should have 1/16” to 1/8” free play before contacting bearing.

- Swaging the tube ends approximately 0.020” overall should be sufficient for retaining the bearing housing.

- Tube diameter decreases in excess of 0.030” are not recommended.

- Each completed roller should be test spun to assure smooth operation.

Any deviation from the recommended practices and procedures should be carefully evaluated.