Urethane Hex Shaft Adapters

Question: What is the best way to protect my conveyor system against frame wear?

Answer: The Ralphs-Pugh Quiet Roller with Urethane Hex Shaft Adapters

As conveyors achieve higher speeds they will vibrate due to roller tubes that are not perfectly round. Over time this vibration/chatter causes the conveyor frame and roller shafts to wear, as illustrated in the pictures. The Ralphs-Pugh urethane hex shaft adapter eliminates frame and shaft wear, and metal to metal contact.

Our “Quiet Roller” features the Urethane Hex Shaft Adapter and ABEC-1 precision ball bearings. The advantages of urethane are wear, tear, abrasion resistance, and the reduction of noise by eliminating metal to metal contact. Coupled with ABEC-1 precision bearings, the “Quiet Roller” provides the ultimate in wear resistance and noise dampening. The result is a quiet conveyor with lower maintenance, repair, and operating costs than a system with standard steel shaft rollers.

To hear the difference contact us for an on-site demonstration or check out our Noise Reduction Demo by clicking here.

Limitations and Considerations

Temperature: Not recommended over 200°F.

Hydrolysis: Can withstand water for years at low temperature. Cannot withstand steam.

Chemicals: Strong acids and bases will degrade urethane rapidly. Inquire before ordering.

Loads: Maximum load per roller is 100 lbs.

Urethane Hex Shaft Adapter FAQ

(Frequently Asked Questions)

Q. Why should I consider conductive urethane hex shaft adapters?

A. Two reasons: a) To eliminate shaft and frame wear caused by traditional metal to metal contact and b) to eliminate noise caused by shaft vibration. Urethane has exceptional wear resistance and noise deadening properties.

Q. My frames are older and vary in width, what will a urethane hex shaft adapter do for me?

A. They will prevent additional wear to the punched hole, greatly reduce the noise level of your system and due to 9/16" standard shaft extensions no further deterioration of the frame should occur. Ralphs-Pugh rollers do not use preload to "lock" the shaft into the punched hole. Our tests indicate that this locking style roller can increase wear and deterioration of frames.

Q. What is the maximum load rating for a roller with conductive urethane hex shaft adapters?

A. The maximum load rating for this style roller is 100 pounds but could be less based on the length of the roller and application. The concept of this adapter is to eliminate noise and wear which are typically caused by shaft vibration in the frame at higher speeds and with lighter loads.

Q. What does conductive mean?

A. When rollers are in motion they build up a static electrical charge. Non-conductive materials do not have the ability to dissipate this electrical charge. Persons coming into contact with the frame can receive painful shocks as this charge now dissipates through the person. Conductive materials allow this static charge to safely pass from the roller to the frame and eventually to ground.

Q. Are there any applications where these adapters shouldn't be used?

A. Yes - In areas where the temperature exceeds 200 degrees Fahrenheit or where steam is used for cleaning and around strong acids or bases.

Q. Can I use these adapters around water?

A. Yes - Urethane can withstand water for years at low temperatures (less than 200 degrees Fahrenheit)

Q. What is inside this adapter to support the load? (i.e. are my mechanics safe on this roller?)

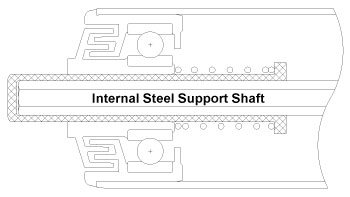

A. The adapter is supported by an internal 5/16" hexagonal steel shaft that extends to within 1/8" of the end of the adapter.

Q. Can this adapter be used in accumulation conveying systems?

A. Yes, the exceptional wear resistance of urethane makes it an ideal choice for this application (similar to urethane engine mounts) with the added benefits of sound reduction and no traditional metal to metal contact causing frame and shaft deterioration.